Revolutionizing Reliability: How SEPCO’s High-Performance Seals Saved a Texas Chemical Plant $336,000 Annually

Background: A Legacy Plant Grappling with Modern Demands

Established in 1990, this Texas-based chemical manufacturing plant specializes in producing high-demand specialty chemicals for industries ranging from pharmaceuticals to agriculture. For decades, it operated smoothly, but as production scaled and environmental conditions grew more aggressive, the plant began experiencing persistent sealing failures. These issues not only disrupted operations but also escalated costs and posed risks to both workers and the surrounding ecosystem.

The Challenge: Costly Seal Failures in a Harsh Environment

At the heart of the problem were the seals in the plant’s main reactors, which were ill-equipped to handle extreme temperatures (often exceeding 200°C) and highly corrosive chemical mixtures. This led to a cascade of operational headaches:

- Frequent Unscheduled Downtimes: Averaging 15 hours per month, halting production lines and delaying shipments.

- Significant Product Losses: Approximately $20,000 monthly due to leaks and contamination, wasting valuable resources.

- High Maintenance and Replacement Costs: Around $10,000 per month in repairs, parts, and labor.

- Safety and Environmental Hazards: Potential exposure to hazardous chemicals, increasing risks for personnel and regulatory compliance issues.

Without a robust solution, these failures threatened the plant’s profitability and long-term viability in a competitive market.

The Solution: Tailored Expertise from SEPCO

SEPCO, a leader in advanced sealing technologies, conducted a comprehensive on-site audit to diagnose the root causes. The assessment revealed that the existing seals lacked the necessary resistance to thermal expansion, chemical corrosion, and abrasive wear. SEPCO’s recommendations focused on a holistic upgrade:

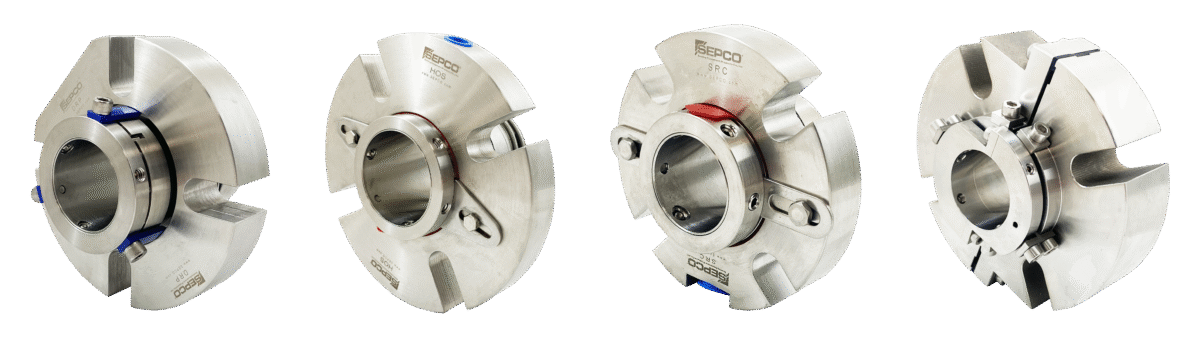

- Advanced Seal Technology: Switching to SEPCO’s proprietary high-performance, corrosion-resistant seals engineered specifically for high-temperature, aggressive environments. These seals incorporate innovative materials like advanced elastomers and reinforced composites for superior durability.

- Proactive Maintenance Protocol: Introducing a structured bi-monthly inspection and predictive maintenance schedule to identify early signs of degradation.

- Staff Empowerment Through Training: A customized program to equip the maintenance team with best practices for seal selection, installation, and troubleshooting.

This multi-faceted approach aimed not just to fix the immediate issues but to build resilience into the plant’s operations.

The Implementation: Seamless Transition with Minimal Disruption

- The upgrade was executed during a planned maintenance shutdown over a single weekend, minimizing impact on production. Key steps included:

- Removing and replacing the outdated seals with SEPCO’s high-performance models across all critical reactors.

- Conducting an intensive two-day training workshop for 15 maintenance staff members, complete with hands-on simulations and real-world scenarios.

- Integrating digital monitoring tools to track seal performance in real-time, allowing for data-driven adjustments.

Post-implementation, the new inspection schedule was rolled out immediately, ensuring ongoing vigilance.

The Results: Dramatic Improvements and Quantifiable ROI

The transformation was swift and profound. In the first three months alone:

Zero Unscheduled Downtimes: Eliminating the 15-hour monthly interruptions entirely.

95% Reduction in Product Losses: Slashing monthly waste from $20,000 to under $1,000.

80% Drop in Maintenance Costs: Cutting expenses from $10,000 to just $2,000 per month.

Over the full year, the plant achieved:

180 Hours of Additional Production Time: Boosting output and revenue potential.

$240,000 Saved in Product Losses: Directly improving the bottom line.

$96,000 Reduced in Maintenance Expenses: Freeing up budget for other investments.

Total annual savings reached $336,000—far exceeding the initial investment in seals and training. Beyond the numbers, the upgrade enhanced workplace safety, reduced environmental impact through fewer leaks, and instilled greater confidence among staff, fostering a culture of proactive maintenance.

Conclusion: The Power of Precision Sealing in Industrial Success

This case study illustrates a universal truth in manufacturing: subpar sealing solutions can erode efficiency, but the right innovations can unlock extraordinary gains. By partnering with SEPCO for customized, high-performance seals and expert guidance, this Texas chemical plant not only resolved chronic issues but also positioned itself for sustained growth. In demanding industries like chemicals, oil & gas, and manufacturing, investing in tailored sealing technology isn’t just smart—it’s essential for minimizing risks, maximizing uptime, and driving profitability.

Ready to Optimize Your Operations? Partner with SEPCO Today

SEPCO delivers cutting-edge sealing solutions for even the most extreme applications, backed by decades of industry expertise across sectors like chemicals, power generation, and food processing. Whether you’re dealing with corrosive fluids, high pressures, or stringent regulations, our team can customize a solution to fit your needs. Contact us to schedule an audit and start saving—because reliable seals mean reliable results.

SEAL CONNECT

SEAL CONNECT

Find Your Sealing Solution

Find Your Sealing Solution