EXP Bearing Isolator featured in Plant Services magazine

Innovative EXP Bearing Isolator was recently included on the Plant Services website as a featured product for 2019.

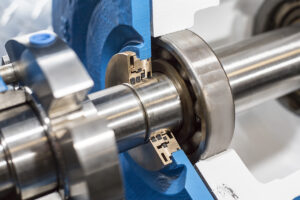

The hybrid design of the EXP Bearing Isolator merges labyrinth technology with a new expeller technology. This makes it ideal for lubricant reliability. The vertical, expeller technology empowers end users to achieve high levels of sealing performance.

According to the Plant Services product listing, “the EXP maximizes bearing and lubricant life by expelling contaminants, eliminating lubrication leakage, and protecting against water contamination.”

No Worn Shafts

Additionally, as a true noncontact bearing isolator, the EXP mitigates worn shafts and sleeves for ensured reliability. Also, it uses a dual expeller to create centrifugal force and drive away contamination. Statically, the EXP dual vertical oriented chambers form the most effective labyrinth on the market.

Configurations

The EXP Bearing Isolator is available in different configurations, including versions for the following applications:

- Steam turbines: EXP-TB is designed for steam turbines. The design coalesces and expels steam before it reaches the bearing housing.

- Gearboxes: EXP-GB is designed for applications where a positive seal is required because of flooded conditions. With this asset, a positive seal is created within the isolator with no parts to wear on the shaft. Common applications are input shafts on gearboxes. Lubrication protection is ensured.

- Flange-mounted applications: EXP-FL includes all the benefits of a standard EXP with the adaptation for flange-mounted applications where pressing the stator is not recommended or possible.

- Pillow block housings: EXP-PB includes all the benefits of a standard EXP with an adaptation to mount within the existing LER/LOR ring grooves of split pillow blocks.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution