Why Seals in Harsh Applications Must Withstand Many Hazards

SEPCO authored an article for Pumps & Systems discussing why seals in harsh applications must be strong and reliable seals.

“Harsh environments challenge the personnel charged with asset reliability and uptime,” the article explains, “Heat, dust, dirt, moisture, steam, salt, sticky fluids, and caustic chemicals are some of the exacting factors that exist in harsh applications—which include those in the oil, gas, and ethanol industries. ”

These challenges are compounded when sealing valves, rotating equipment, and the lubricants that keep rotating assets up and operating. Maintaining or improving reliability becomes a real concern in these assets.

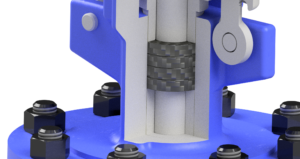

Gate valve illustration with API 622-compliant packing

Process & Oil Seals in Harsh Applications

According to the article, two types of seals are vital for reliable operation when it comes to rotating equipment — process seals and oil seals.

“Process seals seal the pumped fluid and prevent it from leaking out of the pump’s stuffing box or seal chamber to the environment or toward the drive end of the system,” the article explains.

- Some of the process seals that are available for rotating equipment include packing, mechanical seals, elastomeric seals, and magnetic-face seals.

- Oil seals seal the lubrication for the bearing housing and drive. Without an oil seal, any process fluid that may escape the stuffing box or outside contaminants from the atmosphere will contaminate the lubrication, increasing the need for lubricant replacement and the risk of bearing failure.

The three best seals available for lubrication sealing are lip and other elastomeric seals, magnetic-face seals, and bearing isolators.

“Selecting the ideal seal for the process and lubrication is important to improve uptime and reliability,” the article said.

Three Examples

The Pumps & Systems article included three case studies that illustrate how different seal technologies can make an impact in different industries and applications, including:

- API 622 packing for valves

- Mechanical seal system for the ethanol industry

- Bearing isolators for all equipment

Read the full article on PumpsandSystems.com to learn more and explore each case study.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution