How a Bearing Isolator Can Prevent Lubrication Contamination and Save Money

Did you know that lubrication contamination is the No. 1 cause of industrial equipment failure? When lubricants are kept clean and dry, they can offer years of wear protection. However, due to contamination ingress, plants often struggle to achieve months or even weeks of service life between oil changes.

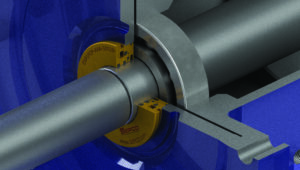

According to a recent pumpsandsystems.com article by SEPCO’s David Brewer and Steve Hall, a well-designed and properly specified oil seal or bearing isolator solves this contamination problem, even in the most challenging applications.

“All bearing isolators are not created equal. Making tweaks to the isolator’s design and selecting technology designed for the equipment type can improve overall performance,” the authors explained.

What Do You Mean By ‘Design Tweaks?’

According to the article, a more straightforward approach can improve bearing lubrication protection.

“Understanding how a bearing system works allows the bearing isolator to be incrementally improved,” Brewer and Hall explained. “This system’s approach examines the bearing housing environment from an energy balance perspective.”

Some bearing isolators have a design tweak that keeps contaminants within the isolator and breaks down their energy to prevent this contamination during static conditions. Here’s what happens in that circumstance:

- The moisture and dust enter the isolator, and the energy is broken down as they are forced through an axial throttling gap and a longer radial gap.

- The contaminants are captured within the internal condensate trap and allowed to drain out through a small static weep hole at the six o’clock position of the bearing isolator.

- And the best part? They never reach the lubricant, even during the shutdown.

What About ‘Equipment-Specific Technology?’

In the article, Brewer and Hall explain that a bearing isolator with a specialized design may be needed for some equipment to protect lubricants fully.

And while most rotating drives will function well with a standard bearing isolator (I.e., many pump and motor arrangements), a design specific to the equipment may be needed if the application is critical or specialized.

Some examples of this equipment-specific technology include:

- Gearboxes

- Pillow blocks

- Steam turbines

- Flange-mounted bearings

You can read the full article on pumpsandsystems.com to learn how a bearing isolator can prevent oil and grease issues, reduce lubricant use, decrease bearing failure, and save money. You’ll also find a case study example from an East Coast paper mill there.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution