Component or Cartridge Seals – Choosing the Right Seal for your industrial application

Mechanical seals can be found everywhere in all industrial processes and applications! Finding the right one, however, is important. The right mechanical seal will ensure that your equipment operates smoothly, without needing constant (and costly) replacement.

What are mechanical seals?

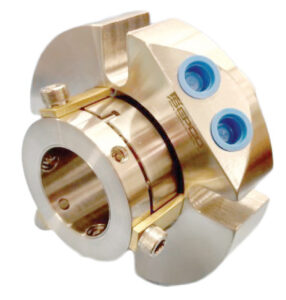

End-face mechanical seals are installed onto rotating shafts in order to keep the correct fluids in, while simultaneously protecting them from contaminants. At their most basic, they consist of a rotating element and a stationary element, each of which is lapped with a precision-smoothed face. The exception to this is air seals which are designed in a way that keeps them from touching the shaft of the equipment. These are very application specific compared to other mechanical seals however and will not be discussed in detail in this article.

Component vs. Cartridge Mechanical Seals

Along with air seals, there are two major types of mechanical seals: cartridges and components. Cartridge-mounted seals are completely self-contained, which allows the unit to be preassembled and preset by the manufacturer before installation. However, whether or not the cartridge seal can be installed depends on several factors, such as proper tension applied to its faces, or if the seal will be installed from the wet side or the dry side of the seal chamber.

Component mechanical seals on the other hand are not preset so installation can be tricky if not done by an experienced pump technician. The sealing housing provides limited access to the components within, so making accurate adjustments to the seal can be tricky. However, they can be less costly upfront than cartridge seals and are more widely applicable.

What to consider when choosing the proper mechanical seal

Two of the most important factors when choosing between these two types of mechanical seals are the cost of the seal and the ease of installation and subsequent replacement during an emergency outage. Another important factor is the application in which the mechanical seal will be used.

Cartridge seals tend to be more cost-effective in the long run despite being potentially more expensive upfront. This is especially true given that pump maintenance is likely to happen and cartridge seals are far easier to install and replace. This results in lower labor costs and less downtime–increased ease of installation reduces the chances that the seal will fail due to improper installation.

However, so long as you have an experienced pump technician on hand to install a component seal, then ease of installation is far less of a concern.

Looking for a supplier of mechanical seals?

SEPCO (Sealing Equipment Products Co., Inc.) is a leading supplier of seals and a variety of other sealing equipment in the fluid sealing industry. Our high-performance solutions can be found across the United States, and around the world. For more information, check out sepco.com!

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution