Bearing Isolators Are Key for Overall System Reliability

Bearing Isolators are vital to any system with rotating equipment. They help to ensure system reliability, protect bearings from environmental contaminants, and keep the lubricant in the housing – where it belongs.

However, bearing protection needs to be addressed regarding equipment reliability, despite the importance of housings and isolators. Premature bearing failure and bearing problems are some of the most common reasons for the failure of electric motors, hydraulic pumps, and many similar systems. Hence the need for isolators to protect them.

How Bearing Isolators Protect Rotating Equipment

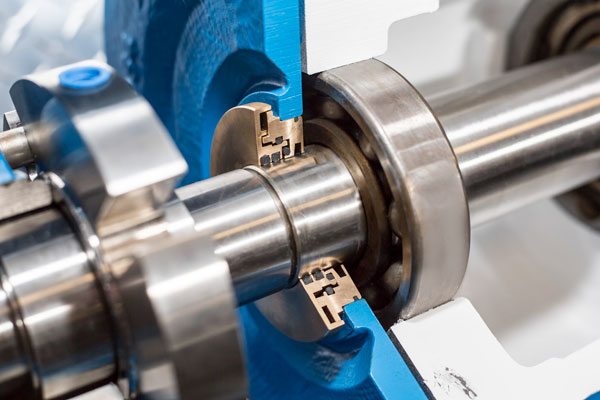

Bearing failures result from many factors, such as over or under-lubrication and lubrication contamination. Bearing isolators help to reduce these problems. They protect the bearing cavity and even expel contaminants that would cause corrosion or other issues, as well as keep the lubricant in its place so that it can keep the components themselves separated. This, in turn, leads to less wear on the bearings and a longer lifespan, leading to better system performance.

The Benefits of Bearing Isolators

Bearing isolators has many other benefits besides protecting the system from contaminants. They encourage efficient equipment functionality, both during the operation itself and when the machine is shut down, protecting it from the exterior environment. They prevent lubrication leaks that might lead to further damage, keeping it within the cavity. There are also several specialized designs for specific equipment needs, such as the ability to operate in extreme temperatures, under heavy loads, or in corrosive environments.

Bearing isolators can also help mitigate misalignments and vibrations that may happen between the stator and rotor. When designed and connected correctly, the isolator can account for shaft deflection and prevent unwanted contact between the stator and rotor. Simpler components don’t provide nearly as much axial control, which can lead to the contact of metallic components during operation.

Why This Matters

Bearing isolators serve as shields for the bearings in rotating equipment. If the bearings fail, so will the equipment, leading to downtime, which is why protecting them is necessary. When the bearings are protected and vital metal components are kept from contact with each other and outside contaminants, your equipment will function more efficiently and reliably over its lifespan.

Looking for a supplier of bearing isolators and other sealing equipment? SEPCO is an industry leader in consistent, quality seals, compression packing, and other sealing products. For more information, be sure to see out our website at www.sepco.com.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution