10/20/2023

Comparative Analysis: Valve Packing vs. High-Performance Plastics in Valve Sealing

| Criteria | Valve Packing | High-Performance Plastics |

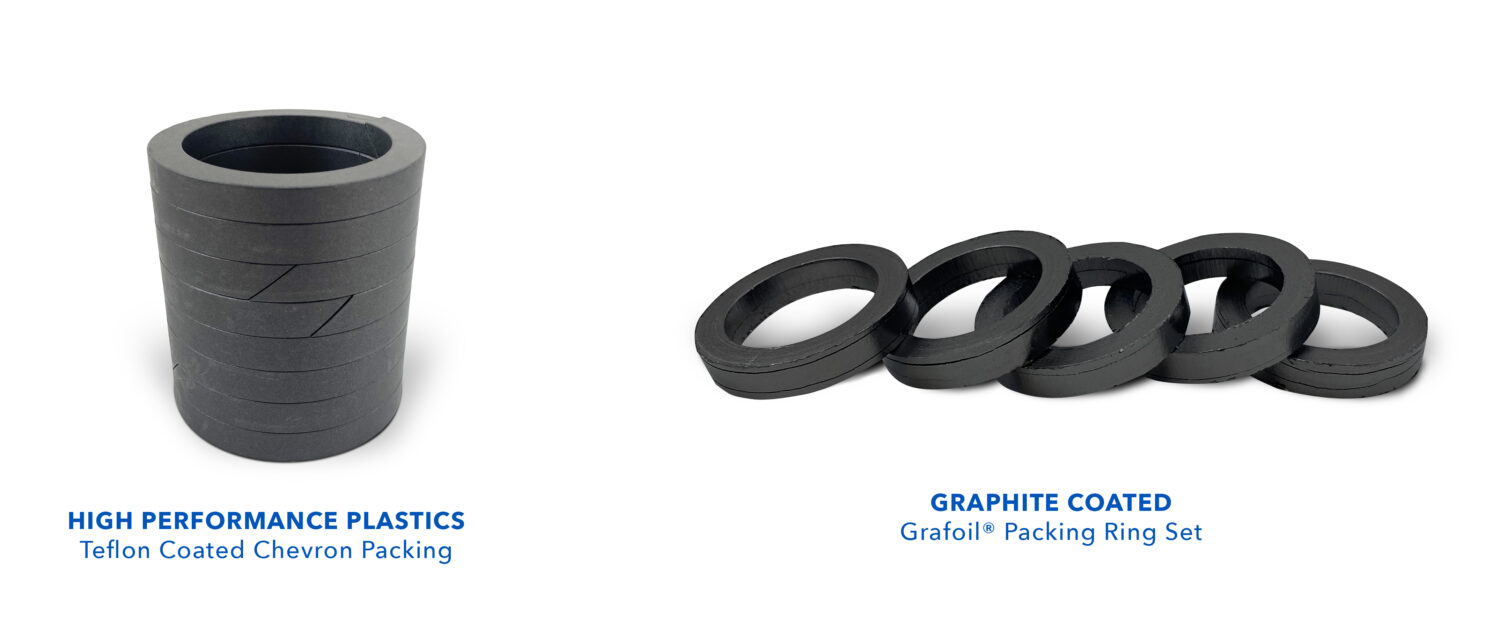

| Material & Composition | Made of fibrous materials such as flax, graphite, PTFE, or aramid, often with lubricants or blocking agents. | Polymers like PEEK, PTFE, PVDF, and PPS designed for demanding conditions. |

| Sealing Mechanism | Uses compressed rings of packing material around the stem. | Precision-machined seals designed to specific tolerances for a tight fit. |

| Applications | Suited for older valve designs and valves with regular stem movement like gate or globe valves. | Preferred in modern valves facing extreme conditions or requiring minimal maintenance. |

| Durability & Maintenance | Can degrade or compress over time, needing periodic tightening or replacement. | Offers extended service life with minimal maintenance, especially in appropriate applications. |

| Performance | Provides a reliable seal for many applications but may struggle with extreme temperatures or aggressive chemicals. | Handles a broader range of temperatures, pressures, and chemicals with superior performance. |

| Cost | Generally less expensive upfront but might have higher maintenance costs over its lifecycle. | More costly initially but can result in lower long-term costs due to reduced maintenance. |

While both valve packing and high-performance plastics are employed to seal valves, they cater to different scenarios and come with distinct advantages and limitations. The decision to use one over the other should factor in the specific requirements of the application, initial budget constraints, and long-term maintenance expectations.

Looking for a Sealing Solutions Provider?

SEPCO has sealing solutions for many applications, even those with the strictest standards and the most challenging environments. We have decades of experience in providing solutions across multiple industries. We can help.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution