Maximizing Pump Lifespan: How to Achieve Reliability in Your Stuffing Box

Achieving stuffing box reliability is crucial for the effective operation of pumps and the prevention of leakage. Ensuring its reliability can minimize maintenance costs, reduce downtime, and extend the lifespan of the equipment. Below are 11 steps to achieve stuffing box reliability:

Achieving stuffing box reliability is crucial for the effective operation of pumps and the prevention of leakage. Ensuring its reliability can minimize maintenance costs, reduce downtime, and extend the lifespan of the equipment. Below are 11 steps to achieve stuffing box reliability:

- Proper Selection:

- Choose the Right Packing or Seal: Whether you’re using compression packing or a mechanical seal, ensure it’s suitable for the specific application, considering the fluid properties, temperature, pressure, and pump speed.

- Ensure Correct Installation:

- Follow Manufacturer Instructions: Adherence to the guidelines provided by the manufacturer can prevent many common issues.

- Check Alignment: Ensure that the shaft or sleeve, gland, and stuffing box are properly aligned.

- Even Compression: For compression packing, apply even pressure to ensure uniform sealing without over-tightening, which can cause excessive heat and wear.

- Regular Maintenance and Inspection:

- Inspect Regularly: Check for signs of wear, damage, or leakage.

- Lubrication: Ensure the lubrication system (if present) works correctly and use the recommended lubricant.

- Cooling and Lubrication:

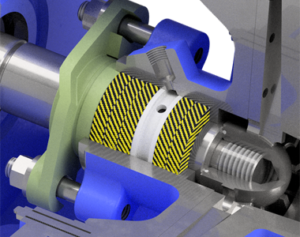

- Use Lantern Rings: If using compression packing, consider installing lantern rings to facilitate even distribution of flush or lubrication.

- Ensure Proper Flush: In cases where an external flush is used, ensure it’s of the right quality and quantity to cool and lubricate the seal or packing.

- Address Cavitation:

- Cavitation can lead to vibration, which in turn can affect the stuffing box’s reliability. Ensure the pump operates away from conditions that induce cavitation.

- Regularly Adjust Compression Packing:

- As the packing wears, periodic adjustments are required to maintain the proper compression to prevent leaks.

- Over time, as adjustments become frequent, consider repacking the stuffing box.

- Monitoring and Data Collection:

- Use Monitoring Equipment: Devices that monitor temperature, vibration, and leakage can provide real-time data on the performance and potential issues.

- Review Operational Data: Regularly analyze collected data to identify patterns that might indicate a looming issue.

- Training:

- Ensure that the maintenance team and operators are trained in best practices for stuffing box maintenance and understand the importance of its reliability.

- Use Quality Components:

- When replacing or installing new components, use high-quality materials and parts that are resistant to wear, corrosion, and have a good track record of performance.

- Environmental Considerations:

- Ensure that the pump and stuffing box are protected from environmental factors that can adversely affect their performance, such as excessive dirt, dust, or corrosive atmospheres.

- Periodic Replacement:

- Recognize that packing and seals have a finite life. Establish and follow a schedule for routine replacements based on wear patterns and manufacturer recommendations.

Achieving stuffing box reliability is a combination of proactive measures, regular maintenance, and responsive actions when issues arise. Ensuring the stuffing box’s reliability can lead to a more extended, trouble-free operational life for the pump and reduce the total cost of ownership.

Looking for a Sealing Solutions Provider?

SEPCO has sealing solutions for many applications, even those with the strictest standards and the most challenging environments. We have decades of experience in providing solutions across multiple industries. We can help.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution