Sealing for Success: Ensuring Purity in Food and Pharmaceutical Processes

Hygienic sealing is critical to maintaining the food and pharmaceutical industry’s cleanliness, safety, and compliance standards. It involves using specialized sealing solutions and practices to prevent contamination, microbial growth, and the introduction of foreign substances in processing equipment, piping systems, and storage vessels. Until the advancements in the last several years, hygienic sealing has long been an issue. Below is an explanation of the importance of hygienic sealing in the food and pharmaceutical industries.

Importance of Hygienic Sealing:

- Product Purity: Product purity is paramount in the food and pharmaceutical sectors. Any contamination in the form of microorganisms, particles, or foreign matter can compromise the quality and safety of the final product. Hygienic sealing ensures that the products remain untainted from start to finish.

- Consumer Safety: The safety of consumers is a top priority in these industries. Hygienic sealing prevents the introduction of harmful bacteria, pathogens, or allergens, reducing the risk of foodborne illnesses and ensuring pharmaceutical products meet stringent safety standards.

- Regulatory Compliance: Food and pharmaceutical industries are heavily regulated, with strict hygiene and quality standards. Hygienic sealing is essential for compliance with regulations such as Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), and Current Good Manufacturing Practices (cGMP). SEPCO understands these regulatory requirements and compliance standards that food and pharmaceutical companies must adhere to. We can provide guidance and solutions that meet these standards,

Critical Aspects of Hygienic Sealing:

- Materials Selection: Hygienic seals are made from FDA-approved, non-toxic, and non-reactive materials. Common choices include food-grade elastomers like EPDM, silicone, and stainless steel for metal components.

- Smooth and Crevice-Free Surfaces: Seals and gaskets must have smooth surfaces without crevices or pockets where contaminants can accumulate. This design feature makes cleaning and sterilization more effective.

- Sanitary Design: Hygienic sealing solutions are designed to meet sanitary standards, including aseptic designs, sanitary clamps, and tri-clamp connections to facilitate easy disassembly and cleaning.

- High Temperature and Chemical Resistance: Seals used in food and pharmaceutical processing must be resistant to high temperatures, cleaning chemicals, and sanitizing agents used in washdown procedures.

- Compliance with Industry Standards: Hygienic sealing solutions should adhere to industry-specific standards such as those outlined by organizations like the Food and Drug Administration (FDA), European Hygienic Engineering & Design Group (EHEDG), and United States Pharmacopeia (USP).

Applications of Hygienic Sealing:

- Food Industry: Hygienic sealing is crucial in food processing equipment such as pumps, mixers, valves, and conveyors. It ensures that the food remains safe for consumption, free from contaminants, and meets the required quality standards.

- Pharmaceutical Industry: In pharmaceutical manufacturing, hygienic seals are employed in various equipment, including reactors, tanks, and filling machines. They help maintain the integrity and sterility of pharmaceutical products.

- Beverage Industry: Hygienic seals play a vital role in the production of beverages like dairy, juices, and soft drinks, where contamination can lead to spoilage and health risks.

- Cosmetic Industry: Similar to pharmaceuticals, the cosmetic industry relies on hygienic sealing to maintain product purity in the production of skincare and personal care items.

Hygienic sealing is a critical component in both the food and pharmaceutical industries. It safeguards product quality, consumer safety, and regulatory compliance by preventing contamination, ensuring cleanliness, and adhering to strict industry standards. Effective hygienic sealing solutions are essential for these industries to maintain their reputation for producing safe, high-quality products.

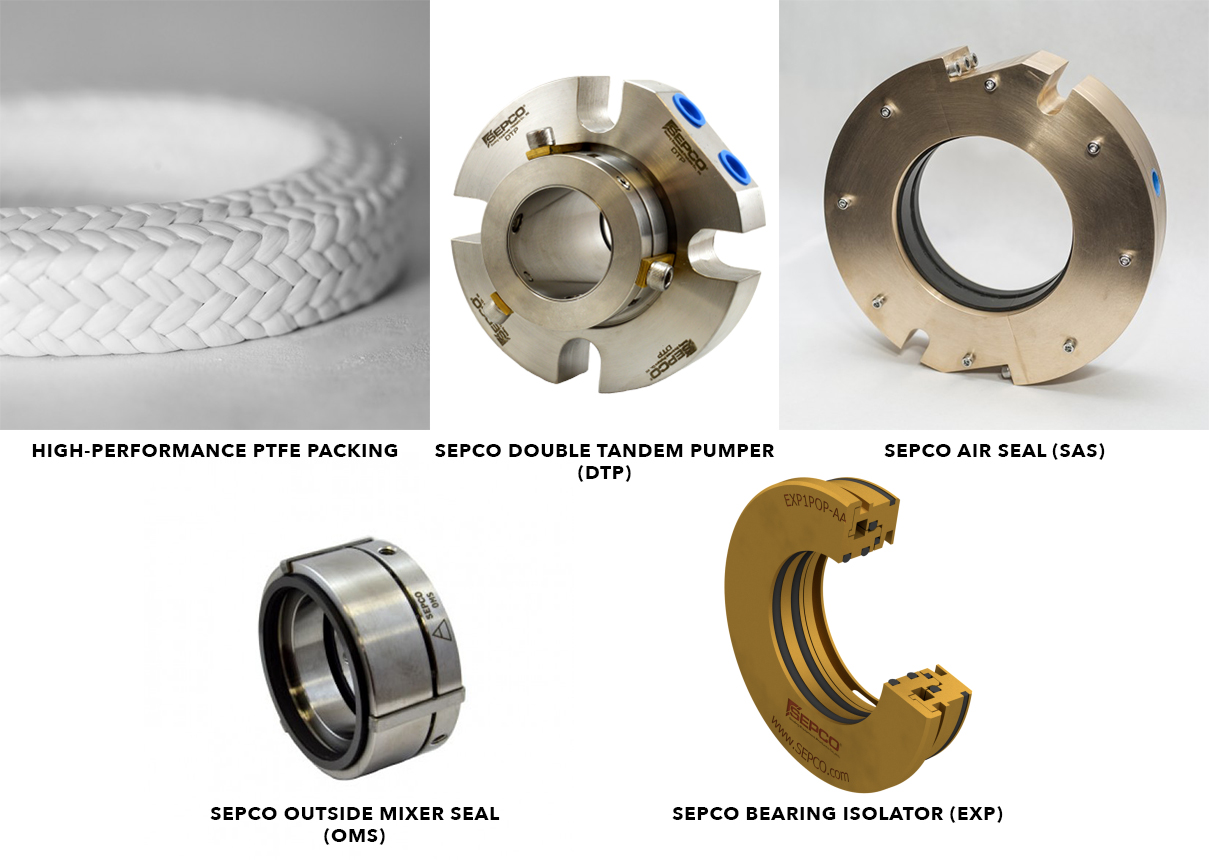

SEPCO offers a wide range of sealing solutions tailored to the specific needs of the food and pharmaceutical industries. Below are just some of the solutions SEPCO can provide:

- Sanitary Packing: SEPCO offers sanitary packing solutions designed to meet the stringent hygiene standards of the food and pharmaceutical industries. These packing solutions help prevent product contamination and maintain cleanliness in processing equipment and pumps.

- High-Performance Plastics: SEPCO provides high-performance plastic components and materials suitable for food and pharmaceutical applications. These materials are often FDA-approved and offer excellent chemical resistance, making them ideal for various sealing and gasketing applications.

- Mechanical Seals: SEPCO offers a range of mechanical seals designed to meet the demands of food and pharmaceutical processing equipment. These seals help prevent leaks, maintain product purity, and ensure equipment reliability.

- Air Seals: SEPCO’s air seal solutions, like the SEPCO Air Seal (SAS), effectively prevent contamination and maintain clean environments in food and pharmaceutical processing. These non-contact pneumatic seals are designed to last the life of the equipment.

- Custom Sealing Solutions: SEPCO can work closely with clients in the food and pharmaceutical industries to develop custom-sealing solutions tailored to their specific equipment and processing needs. This ensures that the sealing solutions are a perfect fit for the application.

- Compliance Assistance: SEPCO understands the regulatory requirements and compliance standards that food and pharmaceutical companies must adhere to. They can provide guidance and solutions that meet these standards, including compliance with FDA, EHEDG, and other industry-specific regulations.

- Technical Support and Training: SEPCO offers technical support and training to help clients in the food and pharmaceutical industries make the most of their sealing solutions. This includes installation guidance, maintenance recommendations, and troubleshooting assistance.

- Environmental Responsibility: SEPCO is committed to providing sealing solutions that contribute to ecological responsibility. Their products help prevent product wastage, reduce emissions, and promote sustainability in the food and pharmaceutical sectors.

- Reduced Maintenance Costs: SEPCO’s sealing solutions are designed for longevity and durability, reducing the frequency of maintenance and replacement. This translates to cost savings for food and pharmaceutical companies over time.

SEPCO’s range of sealing solutions addresses the unique challenges and requirements of the food and pharmaceutical industries, ensuring product integrity, safety, and compliance with industry standards and regulations. You have a problem; We can help.

SEAL CONNECT

SEAL CONNECT Find Your Sealing Solution

Find Your Sealing Solution