Elevating Efficiency: The Central Role of Air Seals

Abstract:

Abstract:

Air seals are fundamental to numerous industrial processes. This document seeks to clarify the underlying concepts of air seals, highlight their importance, and explore their diverse uses in today’s industrial landscape.

- Introduction

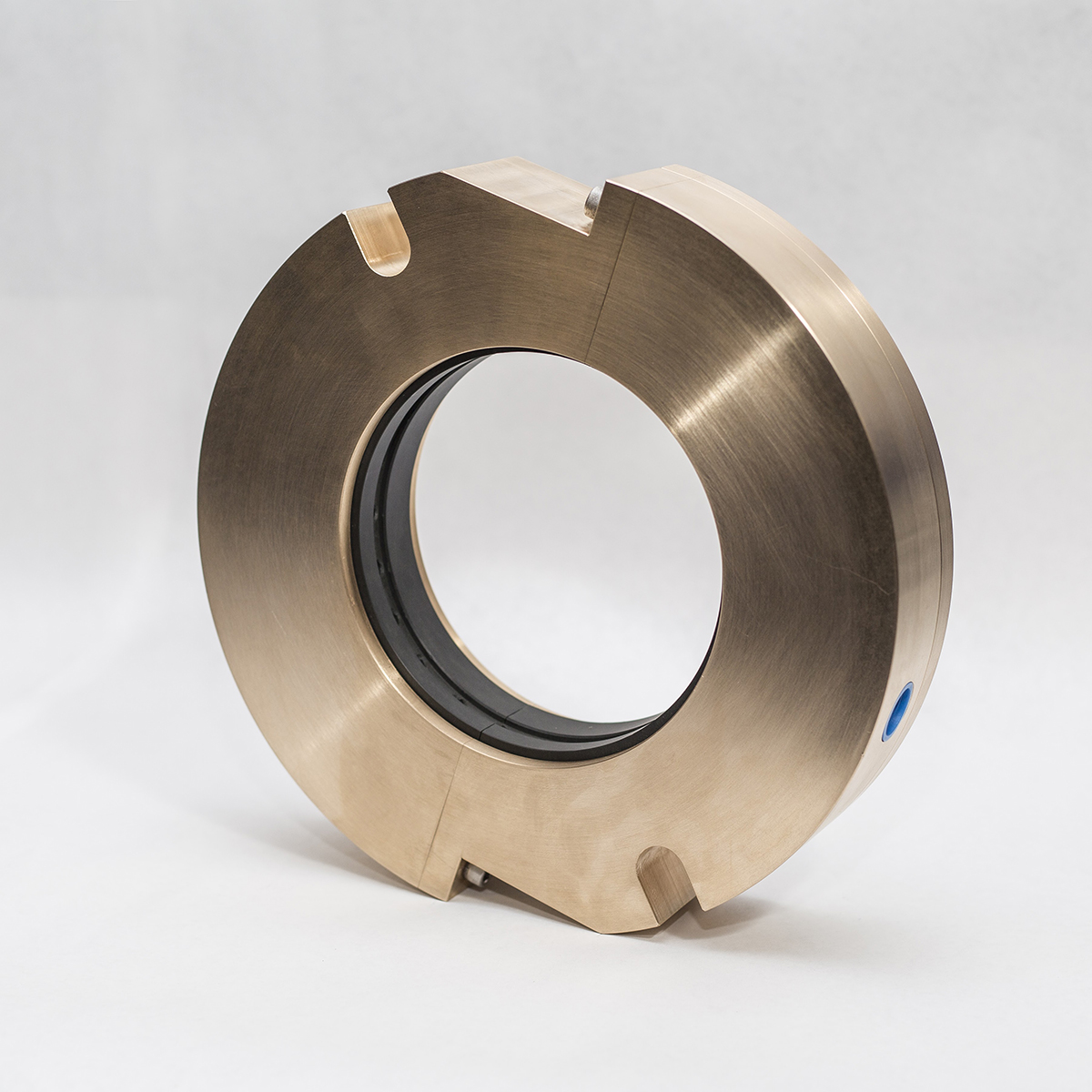

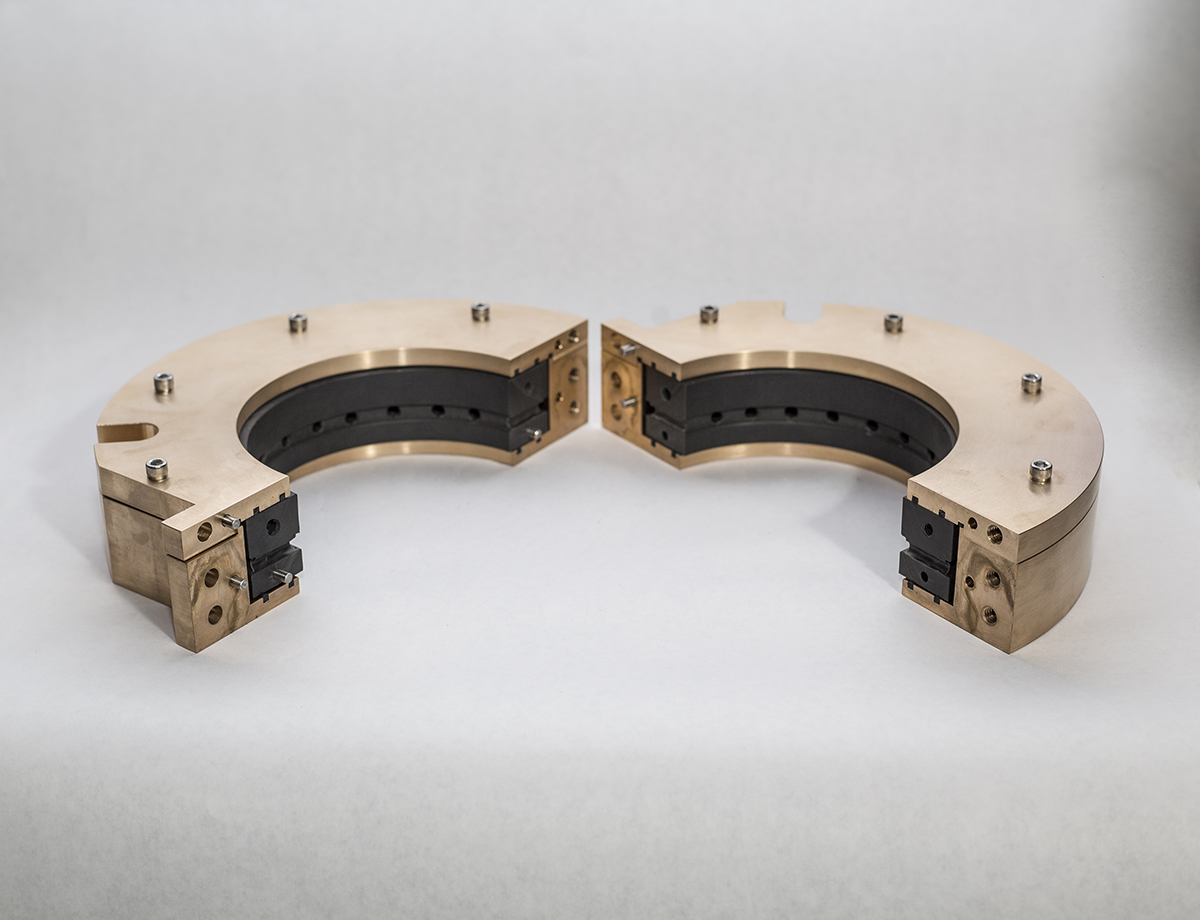

Air seals, as the name suggests, are designed to provide a barrier between two environments, preventing leakage and contamination. These seals work primarily with air or gaseous media, ensuring the integrity of processes and systems.

- Principles of Operation

Air seals operate on the premise of maintaining a thin film of air that serves as a barrier. This film prevents the direct contact of the primary sealed components, mitigating wear and providing a non-contact sealing solution.

- Benefits of Air Seals

- Extended Equipment Lifespan: The non-contact nature reduces wear, enhancing the equipment’s longevity.

- Enhanced Efficiency: By minimizing leakage, the efficiency of the system is inherently improved.

- Reduced Maintenance: Reduced wear means less frequent maintenance, downtime, and related costs.

- Key Applications

- Industrial Machinery: In rotating equipment, air seals prevent contaminants from entering critical systems.

- Pharmaceutical Manufacturing: Air seals ensure a contamination-free environment, crucial for the production of medicines.

- Food Processing: They help in maintaining hygiene standards by preventing unwanted particles from entering production lines.

- Selection Criteria

When choosing an air seal, several factors should be considered:

- Operating Conditions: Including pressure, temperature, and rotational speed.

- Media to be Sealed: The type of gas or air and its potential contaminants.

- Material Compatibility: Ensure the seal materials are compatible with the operating environment.

- Recent Advances

Technological innovations have led to the development of more resilient materials and designs, enhancing air seal efficiency and lifespan. Smart seals equipped with sensors to predict failures are on the horizon, aiming to further revolutionize maintenance practices.

- Summary

Air seals, with their non-contact sealing mechanism, have redefined the standards for various industries. Their widespread application attests to their significance in maintaining the integrity and efficiency of critical systems.

Looking for a Sealing Solutions Provider?

SEPCO has sealing solutions for many applications, even those with the strictest standards and the most challenging environments. We have decades of experience in providing solutions across multiple industries. We can help.

SEAL CONNECT

SEAL CONNECT

Find Your Sealing Solution

Find Your Sealing Solution