Successful Rotating Equipment with Pump Packing Best Practices

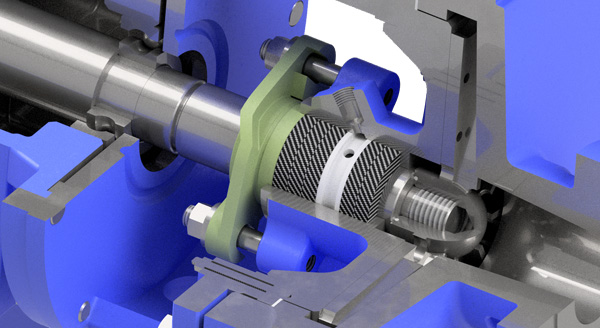

In this downloadable white paper, successful pump packing best practices for successful rotating equipment operation and stuffing box reliability is discussed. All rotating equipment has a stuffing box. Specific to a pump, the stuffing box houses a gland that compresses the packing that seals the pumped fluid. Other rotating equipment has similar stuffing boxes.

Packing prevents leakage along the shaft that passes through a hole in the pump. The reliability of the stuffing box is critical to the condition and performance of the whole fluid sealing program. The better the performance and reliability of a fluid sealing program, the better the condition of the internal pump components, including the stuffing box.

Proper packing installation helps prevent excessive leakage. Shaft stabilization prolongs shaft/sleeve and packing life. Thorough equipment inspections help improve stuffing box reliability. No shortcuts should be taken to ensure ideal overall compression packing performance.

This white paper covers:

- What is compression packing (also called braided packing)?

- Proper packing installation

- Shaft stabilization and water use reduction

- The importance of full equipment inspections

- Best practices for overal packing performance

With proper packing installation, shaft stabilization, and thorough equipment inspections, having a reliable stuffing box and ideal overall compression packing performance is achievable. To learn more, don’t delay. Download this white paper today.

SEAL CONNECT

SEAL CONNECT

Find Your Sealing Solution

Find Your Sealing Solution