Enhancing Food Safety: The Significance of Metal Detectable Polymers

Enhancing Food Safety: The Significance of Metal Detectable Polymers

Introduction:

Metal detectable polymers have emerged as a crucial innovation in the food and beverage industry, providing enhanced safety and traceability in food processing and packaging applications. These polymers, infused with specialized fillers, offer unique properties that enable them to be detected by metal detectors, ensuring product integrity and consumer safety. In this white paper, we delve into the strengths, weaknesses, and applications of metal detectable polymers and the advantages offered by SEPCO Engineered Products in this field.

What are Metal Detectable Polymers?

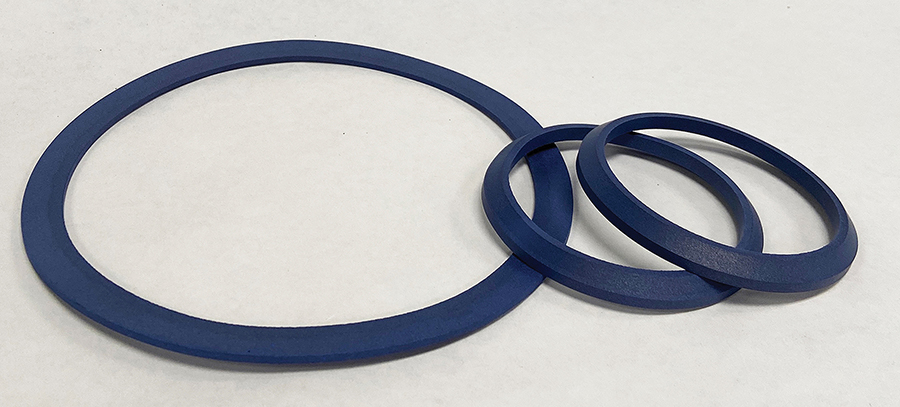

Metal detectable polymers are specially formulated materials used in sealing food and pharmaceutical applications. These polymers contain fillers such as metallic or magnetic particles, making them detectable by metal detectors commonly used in food processing facilities. By incorporating these fillers into the polymer matrix, manufacturers ensure that even small fragments of the seal can be identified and removed from the product stream, reducing the risk of contamination.

Strengths of Metal Detectable Polymers:

- Metal Detectability: The primary strength of metal detectable polymers is their ability to be detected by metal detectors, allowing for quick and efficient identification of foreign objects.

- Minimal Loss of Properties: Despite the addition of fillers, metal detectable polymers exhibit minimal loss of physical and mechanical properties compared to virgin materials, ensuring reliability and performance.

- Chemical and Temperature Resistance: These seals maintain excellent chemical and temperature resistance, making them suitable for a wide range of food and pharmaceutical applications.

- Color Coding: Metal detectable polymers can be color-coded for department or equipment traceability, enhancing product control and management.

Weaknesses of Metal Detectable Polymers:

Minor Loss in Properties: While metal detectable polymers retain most of their properties, there may be a slight decrease in tensile strength, elongation, and permeability compared to virgin materials. However, these losses are minimal and do not significantly impact performance.

Applications of Metal Detectable Polymers:

Metal detectable polymers find diverse applications across various industries, including:

- Food Packaging (bags, films, containers)

- Food Production (spices, flavorings, additives)

- Food Processing (dairy, cheese, rendering)

- Cosmetics

- Pharmaceutical

SEPCO Advantages:

SEPCO Engineered Products offers several advantages in the realm of metal detectable polymers:

- In-House Manufacturing: Our products are manufactured in-house, right here in Texas, allowing for strict quality control and testing at every stage of production.

- Optimal Detectability: We carefully formulate and test every batch of metal detectable polymers to guarantee optimal detectability, providing peace of mind to food and beverage manufacturers.

- Reliability and Safety: With SEPCO products, customers can trust the cleanliness, reliability, and safety of their sealing solutions, which meet stringent industry standards.

- Fast Turnaround: We understand the importance of timely delivery, which is why we can ship products in days rather than weeks, ensuring minimal disruption to production schedules.

Conclusion:

In conclusion, metal detectable polymers represent a significant advancement in food and beverage packaging and processing, offering enhanced safety, traceability, and peace of mind to manufacturers and consumers alike. With SEPCO Engineered Products at the forefront of innovation in this field, customers can expect reliable, safe, and efficient sealing solutions that meet the rigorous demands of the food and beverage industry.

For more information about SEPCO’s metal detectable polymers and sealing solutions, please visit our website or contact us directly.

SEPCO Engineered Products – Leading the Way in Food Safety and Traceability

SEAL CONNECT

SEAL CONNECT

Find Your Sealing Solution

Find Your Sealing Solution